Thermal Deburring and Ultrasonic Washing

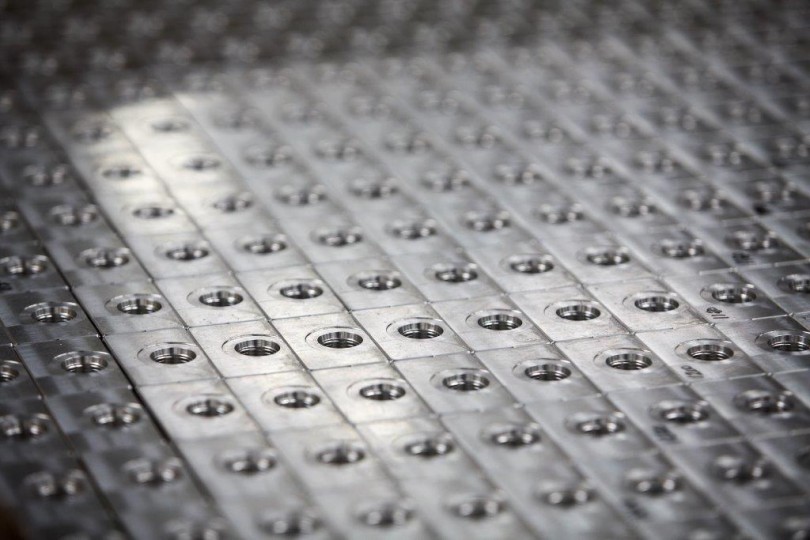

In hydraulic components where there are extremely high demands for purity, we are using thermal deburring just to ensure that the products are 100% clean and burr-free.

Thermal deburring removes all burrs under a controlled explosion. The deburring is carried out under a bell, which is filled with oxygen and natural gas under pressure. A small spark initiates the explosion when the temperature reaches 2500-3300 degrees Celsius, and the burrs are burned away. It’s all over in a split second, but the process requires considerable experience and understanding of the handling of each item.

The items will have an initial and subsequent ultrasonic cleaning in a fully automatic washing machine in the most environmentally friendly methods. They will also undergo corrosion-resistant passivation and subsequent vacuum drying.

Deburring and ultrasonic cleaning achieves a uniform, clean and economically attractive product. MillPart offer thermal deburring and ultrasonic cleaning of all types of materials.