Precision. Automation. High technology.

Complex hydraulic components and precision parts manufactured on advanced CNC machines for the aerospace, defence, and energy industries.

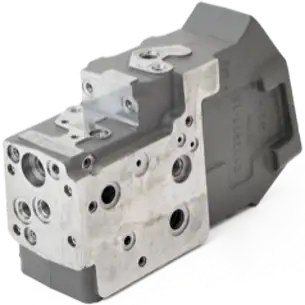

Specialists in hydraulic manifold blocks

Our core competence is the machining of manifold blocks and related components with tight tolerances and strict documentation requirements. We develop process plans based on 3D models and manage production through automated FMS lines and robotic cells operating in four-shift rotation, 24 hours a day, six days a week.

Technical consultancy and collaboration

Complex machining

Søren Christian Dahl

, CEO, MillPart

Production by specification

Machining based on 3D models and defined process parameters.

Components are manufactured according to customer specifications using process plans that define tooling, fixturing and measurement points. Each operation is digitally documented, and the production flow is validated through measurement reports and process data to ensure accuracy and traceability.

Special processes

Honing, thermal deburring and ultrasonic cleaning.

Deburring is performed using a thermal explosion deburring (TED) process, which removes micro-burrs from internal channels without affecting geometry or surface integrity. Subsequent ultrasonic cleaning ensures particle cleanliness and is documented according to customer specifications and hydraulic system requirements.

Surface treatment

Process control and documentation through certified partners.

Surface treatments are carried out externally by qualified partners operating according to EN/AS 9100 requirements and documented processes. Treatment types and specifications are defined in collaboration with the customer and fully integrated into the overall production flow.