Aerospace

We manufacture precision components in accordance with AS9100 requirements, supported by documented process control, measurement reports, and FAI documentation.

Certified manufacturing for aerospace

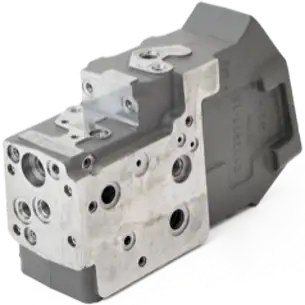

We manufacture hydraulic manifolds, valve housings, and components for control and fuel systems in civil and military aircraft. Production processes are managed in accordance with EN/AS 9100, and each component is approved with First Article Inspection (FAI) documentation in accordance with AS9102.

Tight tolerances and documented process control

Typical tolerances range from 0.005 to 0.015 mm on critical geometries. All measurements are recorded digitally, and deviations are managed through documented process control. Surfaces and flow channels are treated using honing, thermal deburring, and ultrasonic cleaning to verify tightness and flow performance.

Each component is traceable back to the CAM program, tool number, and in-process measurements. This enables full documentation of the relationship between design and machining. Our machine park operate in four-shift rotation, allowing aerospace projects to be executed in stable series without variation.