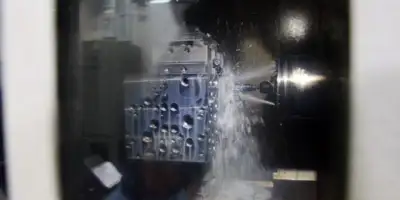

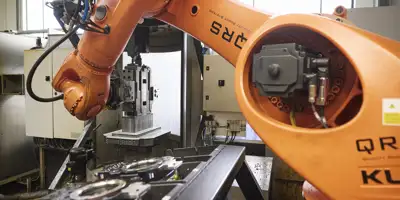

Production by specification

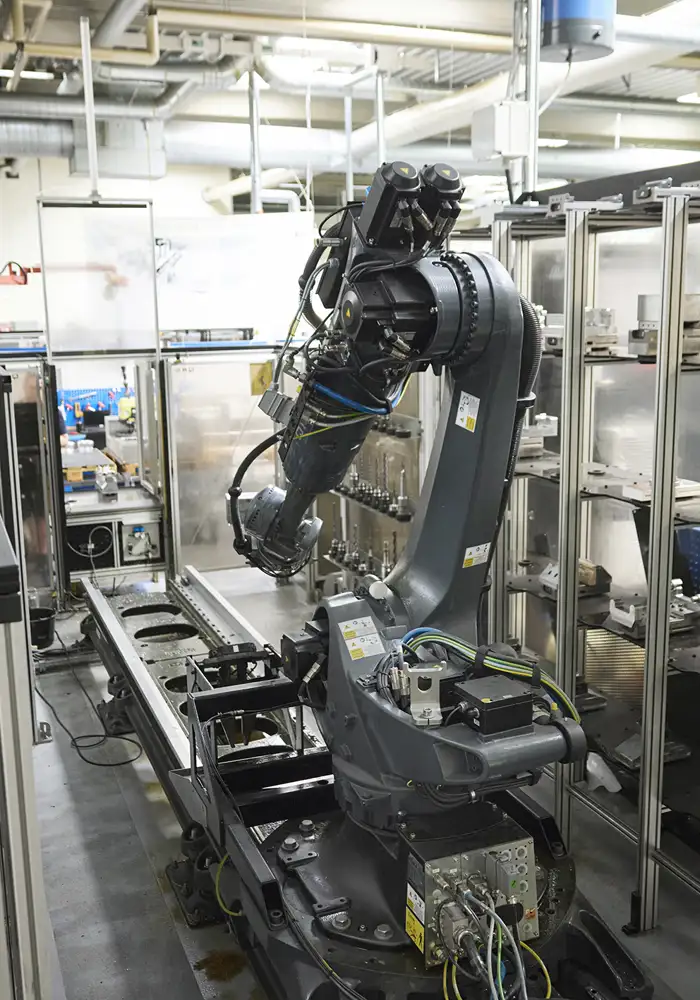

We machine components based on customer 3D data and defined tolerances. Each process is planned with fixed measurement points and documented in real time.

Digital process planning

We follow international standards

Documentation follows international standards such as AS9102, PPAP, and APQP, and our quality management system is certified to EN/AS 9100. All materials, tools, and measurement points are digitally traceable throughout the entire production process.

Programming and CAM integration

Programming is performed using Siemens NX, Mastercam, Mazacam, and CATIA, which are used for design, simulation, and machining strategy. These systems allow customer CAD data to be transferred directly into the CAM environment, where tool paths and machining sequences are virtually optimized. Each machine receives the validated program directly from the server, ensuring machining without manual conversions.