Automation

Robotic cells and FMS lines drive production in continuous flow. Automated tool management and in-process measurement ensure consistent machining quality and documented results across every production series.

Fully automated production in a unified flow

We use fully automated production systems that integrate machining, material handling, and process monitoring into a single, unified flow. Automation is a prerequisite for stable quality and continuous operation.

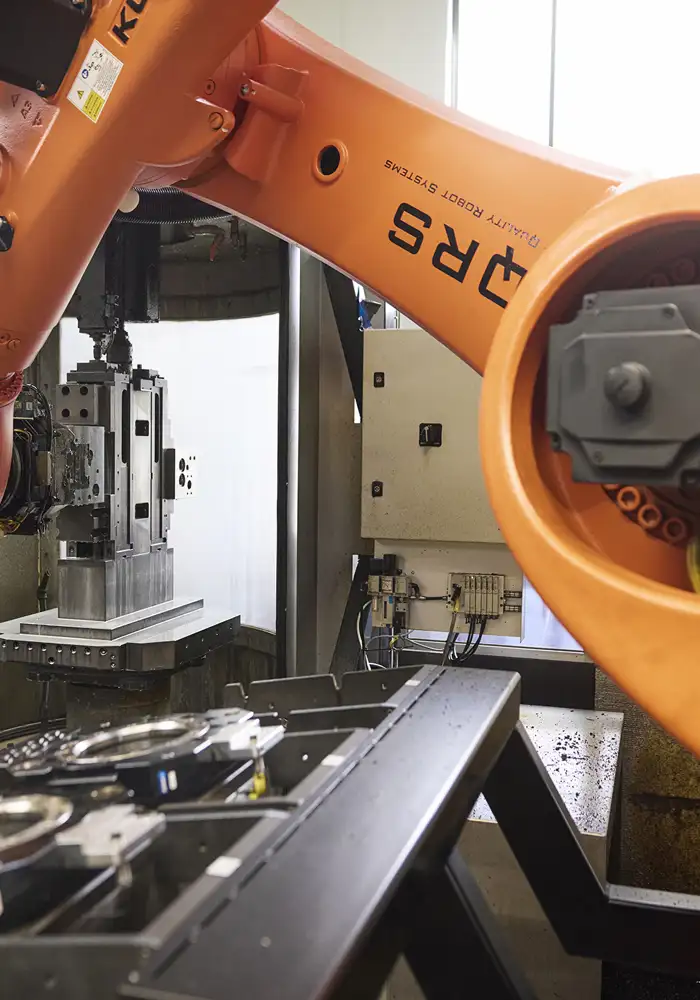

Four robot-controlled FMS lines handle machining on three-, four-, and five-axis machines. Each line is equipped with AGV transport and automated pallet and part handling, allowing machines to operate without manual intervention for up to 24 hours at a time.

Automated process control and real-time documentation

Robot-controlled FMS lines for continuous operation

Process data is transferred directly between machines and control systems. Tool management, program selection, and measurement points are controlled automatically, and the system records all production parameters for each individual component. This structure makes it possible to maintain consistent process accuracy while documenting the entire production process in real time.

Automation supports the special processes that require close integration. Components undergoing honing, thermal deburring, and ultrasonic cleaning are moved through defined sequences without manual handling. This reduces variation and ensures that all steps are performed within specified tolerances and cleanliness requirements.

Integrated special processes with minimal variation

For projects with repeat series, this means that setups, process routes, and documentation can be recalled without adjustment. The production flow remains constant regardless of batch size, and traceability is maintained from the first to the last component.